info@roller-shutter.uk 01392270218

Cheek Plates (End Plates) for Roller Shutters: Foundation of Strength and Stability

When it comes to the reliability and longevity of any roller shutter installation, the quality and correct specification of structural components are paramount. Among these, the cheek plates—also known as end plates—play a vital role in supporting the entire shutter assembly. At HVP Security Shutters, we ensure every system is engineered with robust, precisely fitted cheek plates to guarantee safe and secure operation for years to come.

What Are Cheek Plates (End Plates)?

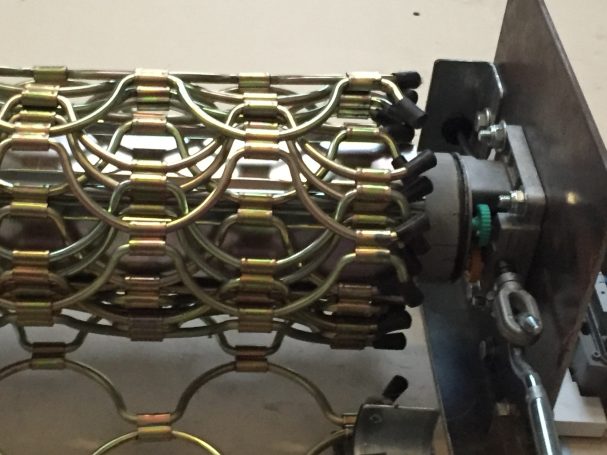

Cheek plates, or end plates, are heavy-duty, load-bearing steel components positioned at either end of the shutter barrel. Their primary function is to support the roller mechanism that holds and moves the shutter curtain. By anchoring the roller securely to the building structure, cheek plates provide the essential foundation for the shutter’s smooth and reliable operation.

Key Features and Functions

Load-Bearing Support: Cheek plates are designed to withstand the full weight and dynamic forces of the roller shutter, including the curtain, barrel, and motor assembly. This ensures stability during both daily use and emergency operation.

Secure Fixing: Each cheek plate is firmly attached to the building using specialist fixings, tailored to the substrate and load requirements. Proper installation is critical for both safety and compliance with UK standards.

Alignment and Operation: Cheek plates maintain precise alignment of the roller and curtain, preventing operational issues such as jamming, excessive wear, or uneven movement.

Integration with Other Components: Cheek plates often serve as mounting points for additional elements, such as flag posts, canopies (hoods), and side guides, contributing to the overall strength and integrity of the shutter system.

Why Are Quality Cheek Plates Important?

Safety: Robust cheek plates prevent the shutter assembly from becoming loose or unstable, reducing the risk of accidents or property damage.

Durability: High-quality materials and expert installation minimise wear and tear, extending the service life of the shutter.

Compliance: All HVP Security Shutters installations are carried out in accordance with relevant UK and European standards, ensuring that cheek plates are specified and fitted to meet statutory requirements.

Performance: Properly engineered cheek plates contribute to the smooth, quiet, and reliable operation of your roller shutter, even in demanding environments.

Applications

Cheek plates are an essential component in all types of roller shutters, including:

Commercial and industrial shutters

Fire-rated and security shutters

Retail shopfronts and residential installations

Custom and large-scale projects

HVP Security Shutters: Built on a Foundation of Quality

With over three decades of experience, HVP Security Shutters is committed to delivering roller shutter systems that are as robust as they are reliable. Our engineers specify and install every cheek plate with meticulous attention to detail, ensuring your shutter is built on a solid foundation.

For technical advice, site surveys, or to discuss your next project, contact HVP Security Shutters.