info@roller-shutter.uk 01392270218

Manual vs. Electric Roller Shutters: The Ultimate Guide to Choosing Your Ideal Solution

Roller shutters are a popular and highly versatile solution for enhancing security, boosting energy efficiency, and ensuring privacy in both residential and commercial properties. These robust coverings act as a formidable barrier, offering protection against intruders, extreme weather conditions, and unwanted noise. When considering the installation of roller shutters, one of the most significant decisions property owners face is whether to opt for manual or electric operation. This choice profoundly impacts everything from the initial investment and daily convenience to long-term reliability and ongoing maintenance requirements. This comprehensive guide will delve into the mechanisms, advantages, disadvantages, costs, reliability, and typical use cases for both manual and electric roller shutters, providing a detailed comparison to help individuals make an informed decision tailored to their specific needs and budget.

Understanding Roller Shutters: Core Components & Universal Benefits

Regardless of their operational method, all roller shutters share fundamental components that enable their protective and functional capabilities. Understanding these parts is essential to appreciating how these systems work.

Key Components

The primary elements of a roller shutter system include:

- Curtain: This is the most visible part of the shutter, comprising precision roll-formed or extruded interlocking profiles, typically made from aluminium, steel, or PVC. The curtain forms the main barrier that moves vertically within the side guides.

- Axle/Roller Tube: Housed within the headbox, this component is responsible for the curtain's upward and downward movement. The curtain rolls tightly around the axle when opening, and unwinds from it when closing.

- Guide Channels/Rails: These are aluminium extrusions installed vertically on each side of the window or door opening. They securely hold the roller shutter curtain in place and ensure its smooth, guided movement during operation.

- Bottom Bar: An aluminium extrusion that interlocks with the lowest profile of the roller shutter curtain. It provides additional strength, offers a neat finish, and often incorporates a locking mechanism, particularly for manual roller shutters.

- Pelmet/Canopy Cover: Also referred to as the hood or headbox, this durable aluminium cover is designed to enclose the internal components, such as the axle and rolled-up curtain, protecting them from external elements and debris. Installing a pelmet is highly recommended as it not only improves the overall aesthetic appeal but also significantly enhances the shutter's longevity by safeguarding its internal workings.

- Side Frames/End Plates: These are load-bearing structural components, also known as end plates, that support the pelmet and all internal roller shutter mechanisms, including the axle. They must be securely fixed to the building structure to ensure stability and proper function.

Shared Advantages of All Roller Shutters

Beyond their operational differences, all roller shutters deliver a range of universal benefits that contribute to enhanced property comfort and security:

- Enhanced Security: Constructed from strong, robust materials, roller shutters serve as an excellent deterrent against burglars and vandals, making forced entry exceptionally difficult. They can be securely locked from both the inside and outside, providing a formidable layer of protection for any property. Electric options often incorporate advanced motor locking mechanisms, further bolstering security.

- Energy Efficiency & Insulation: Roller shutters act as an effective insulating barrier, significantly contributing to temperature regulation within a property. By preventing heat from escaping during colder months and blocking excessive heat gain in summer, they can substantially reduce energy bills and decrease reliance on heating and air conditioning systems.

- The effectiveness of roller shutters in providing thermal insulation and noise reduction is primarily determined by the materials used in their construction and the quality of their installation, rather than the method of operation (manual or electric). For instance, shutters made with thicker, denser materials, especially those with insulated slats (such as polyurethane foam-filled aluminium or steel), are far more effective at blocking sound and regulating temperature. A closed roller shutter can more than double the R-value (a measure of thermal resistance) of a standard window, potentially increasing it from R 2.1 to R 4.25, leading to significant energy savings. This means that while electric shutters might offer programmable features for energy optimization, the core benefit of insulation comes from the physical properties of the shutter itself and how tightly it seals against the opening.

- Noise Reduction: These shutters provide a substantial barrier against external noise, helping to create a quieter and more peaceful indoor environment. This benefit is particularly valuable for properties located on busy streets or in noisy urban areas. Insulated roller shutters can reduce external sound by up to 35 dB, and in some cases, even up to 50%, effectively transforming a noisy outdoor environment into a tranquil indoor sanctuary.

- Increased Privacy: When fully closed, roller shutters offer complete privacy, shielding the interior of a property from outside view. They also provide precise control over the amount of natural light entering a room, allowing occupants to create a comfortable and desired ambiance.

- Weather Protection: Roller shutters are highly effective at protecting properties from extreme weather conditions. They are designed to withstand high winds, heavy rain, and even hail, safeguarding windows and doors from damage. Additionally, they protect internal furnishings and flooring from fading caused by harmful UV rays.

- Versatility & Aesthetics: Available in a wide array of sizes, colors, and materials, roller shutters are incredibly versatile. They are commonly installed on windows and doors but are also widely used for garages, warehouses, and various commercial and industrial settings. Their customizable nature ensures they can complement virtually any architectural style, enhancing a property's curb appeal.

Manual Roller Shutters: Simplicity, Affordability, and Traditional Reliability

Manual roller shutters represent the traditional approach to property protection, offering a straightforward and cost-effective solution.

How They Work (Mechanism)

Manual roller shutters operate through direct physical engagement. The shutter curtain moves vertically along guide tracks, rolling onto an axle housed within the headbox. This axle is driven by various manual mechanisms, including:

- Strap/Cord/Steel Cable Winders: The most prevalent methods involve a strap, cord, or steel cable connected to the roller assembly. This is manually wound or unwound via a winder box, which typically features a handle or pulley system mounted inside the property, usually adjacent to the window or door.

- Spring-Loaded with Key Lock: Some manual systems incorporate a spring mechanism to assist with the lifting and lowering of the curtain, reducing the physical effort required. These are often combined with a key lock at the bottom bar for enhanced security when the shutter is fully closed.

When lowering the curtain, the axle rotates in the opposite direction. Upon reaching the bottom, the interlocking slats of the curtain fully close, providing a secure and protective barrier.

Pros of Manual Roller Shutters

Manual roller shutters offer several distinct advantages:

- Lower Upfront Cost: They are generally less expensive to purchase and install compared to their electric counterparts, making them an attractive option for budget-conscious homeowners and small businesses. For residential windows, basic manual shutters can start from as low as £138-£150, while manual roller garage doors typically range from £750-£1,400 including supply and installation.

- No Power Dependency: A significant advantage of manual shutters is their ability to operate without electricity. This ensures full functionality even during power outages or emergencies, providing uninterrupted security and peace of mind, particularly in areas prone to unreliable power supply.

- Simpler Installation: Manual shutters typically involve a less complex installation process as they do not require intricate electrical wiring or connections to the main power supply.

- Fewer Components: Without a motor or elaborate electrical system, manual shutters have fewer mechanical parts that can malfunction. This can translate to less frequent technical issues and potentially simpler, more straightforward repairs when problems do arise.

- Environmentally Friendly: As they do not consume electricity for their operation, manual shutters contribute to energy conservation and a reduced carbon footprint.

Cons of Manual Roller Shutters

Despite their benefits, manual shutters come with certain drawbacks:

- Requires Physical Effort: Operating manual shutters can be cumbersome and physically demanding, especially for larger or multiple windows. This makes them challenging for some homeowners, particularly elderly individuals, people with disabilities, or those with mobility issues.

- Less Convenient & Time-Consuming: Each shutter must be individually opened and closed by hand, which can be inconvenient and takes more time compared to automated options. This is particularly noticeable during extreme weather conditions or for properties with numerous openings.

- Not Ideal for Large Openings: Larger and heavier shutters are often too cumbersome and potentially unsafe to lift or lower using a manual winding mechanism. This limitation restricts their suitability for big windows, wide doorways, or most commercial and industrial applications where substantial size and weight are common.

- Potentially Less Secure (Compared to Electric): While manual shutters offer strong basic security, they are generally considered easier for intruders to lift and overcome compared to electric options, which typically feature a robust motor locking mechanism that provides an additional layer of resistance.

- Unsightliness of Winder Mechanism: The internal winder mechanism, including visible cords, tapes, or winder boxes mounted inside the home, can be considered aesthetically unappealing by some property owners.

- Lower Resale Value: Homes equipped primarily with manual shutters may attract lower resale prices compared to those featuring modern, motorized options, which are often perceived as adding greater convenience and security benefits.

Typical Use Cases

Manual roller shutters are typically chosen for specific applications where their advantages outweigh their limitations:

- Smaller Windows: They are ideal for smaller window openings where the physical effort required for operation is minimal and the added convenience of automation is not a primary concern.

- Budget-Conscious Installations: For homeowners or small businesses seeking an affordable security solution without a large upfront investment, manual shutters present a practical choice.

- Areas Prone to Frequent Power Outages: Their independence from electricity ensures uninterrupted operation and security, even when the power supply is unreliable.

- Low-Traffic Garages or Small Commercial Premises: In environments where shutters are opened and closed infrequently, the manual effort becomes less of a daily burden, making them a suitable and cost-effective option.

Maintenance & Common Problems

Maintaining manual roller shutters involves relatively straightforward tasks, but consistent attention is key to their longevity.

- Regular Cleaning & Lubrication: To ensure smooth operation and prevent common issues, the tracks, guides, and all moving parts (such as gears, rollers, hinges, and springs) should be regularly cleaned to remove accumulated dirt and debris. Periodic lubrication is also essential to reduce friction and maintain effortless movement.

- Common Problems:

- Difficulty Opening or Closing/Jamming: This is a very common issue, often stemming from accumulated dirt or debris within the tracks, misalignment of the shutter curtain, or a stiff mechanism due to insufficient lubrication. Obstructions or worn-out components like the pulley system or roller guides can also cause the shutter to jam.

- Derailed or Broken Cables/Straps: Through regular wear and tear, the shutter's operating cable, cord, or strap can come off its roller assembly or break entirely, leading to the shutter becoming stuck or even slamming shut unexpectedly. Repair typically involves opening the pelmet to re-rail or replace the damaged component.

- Broken or Uneven Slats: Individual slats that are damaged, bent, or misaligned can prevent the entire shutter from rolling smoothly, causing buckling or gaps and compromising both security and insulation.

- Noise During Operation: Unusual noises such as rattling, squeaking, or grinding can indicate a lack of lubrication in moving parts or loose components that require tightening.

- Lifespan: While manual shutters are generally durable due to their simpler mechanical design, they can experience faster wear and tear, particularly with heavy or frequent use, or if maintenance is neglected. Regular and diligent maintenance is therefore crucial to extend their operational lifespan. A professional annual service is generally recommended to identify and address potential issues early.

- Although manual shutters are often praised for their simplicity and "fewer components," which might suggest inherent reliability, the nature of their operation introduces a specific type of wear. The direct physical effort applied by the user, coupled with the friction on components like cables, cords, straps, and pulley wheels, means these specific parts are subjected to repetitive stress. This direct, human-induced mechanical stress can lead to quicker wear and tear on these high-friction components, resulting in common issues like derailment or breakage of the operating mechanism. Therefore, while the overall system might be less complex than an electric one, the frequent physical interaction can lead to a shorter lifespan for certain critical operating parts if not regularly maintained. This means "low maintenance" for manual shutters often refers to the type of maintenance (simple cleaning and lubrication) rather than necessarily a lower frequency of issues under consistent or heavy use.

Electric Roller Shutters: Convenience, Automation, and Modern Security

Electric roller shutters represent the modern evolution of property protection, prioritizing convenience, advanced automation, and enhanced security features.

How They Work (Mechanism)

Electric roller shutters are powered by an electric motor, which is typically housed discreetly within the roller tube (the axle) itself, connected to the main power supply. This motor drives the winding and unwinding of the shutter curtain.

- Control Mechanisms: Operation is effortless, activated with a simple touch of a button via various control options:

- Wall-mounted switches: A fixed control panel installed inside the property provides a convenient point of operation.

- Wireless remote controls: These allow for operation from a distance, offering flexibility and ease of use from anywhere within range.

- Smart home systems: For the ultimate in modern convenience, electric shutters can be integrated into existing smart home ecosystems. This enables advanced control options such as voice activation (e.g., via Google Home or Amazon Alexa), mobile app control from a smartphone or tablet, and even scheduled operation.

- Automation: Many electric shutters offer programmable settings, allowing them to open or close automatically at specified times of the day. More advanced systems can even react to external conditions, such as intense sunlight or changing weather patterns, via integrated sensors, optimizing energy efficiency and comfort without manual intervention.

- Motor Sizing: A critical aspect of electric shutter performance and longevity is the selection of a tubular motor with adequate power for the shutter's specific size and weight. An undersized motor attempting to operate a large or heavy shutter can lead to overload, premature breakdown, or even burnout, compromising the system's reliability.

Pros of Electric Roller Shutters

Electric roller shutters offer a compelling array of benefits:

- Effortless Convenience: The primary advantage is unparalleled ease of use. Shutters can be opened and closed with the simple touch of a button, making them ideal for hard-to-reach windows, large openings, or for individuals with limited mobility who might struggle with manual operation.

- Automation & Smart Home Integration: Electric systems allow for multiple shutters to be controlled simultaneously or programmed to operate on a set schedule. Their compatibility with smart home systems means they can be voice-controlled, managed via mobile apps, and even linked with weather sensors for automatic closure during extreme conditions, providing both convenience and improved energy management.

- Enhanced Security: Electric shutters provide superior security due to their integrated motor locking mechanism, which makes them significantly harder for intruders to lift or force open compared to manual options. Some advanced systems can also be integrated with existing alarm systems for an added layer of protection.

- Suitable for Large Openings: Unlike manual shutters, electric systems are perfectly suited for much larger door and window openings, as physical strength is not a limiting factor for their operation. This makes them ideal for wide commercial storefronts, large patio doors, or expansive garage entrances.

- Cleaner Aesthetics: With the motor discreetly housed within the roller tube and no visible cords, tapes, or winder boxes required inside the home, electric shutters offer a sleeker, more modern, and uncluttered appearance.

- Faster Operation: Electric systems generally open and close faster than manual ones, which can significantly improve daily operational efficiency, especially in busy commercial or industrial environments where speed is critical. This rapid operation also contributes to better insulation by minimizing the time the opening is exposed to external elements.

- Increased Property Value: Installing modern, motorized roller shutters can enhance a property's curb appeal and potentially increase its resale value, as they are viewed as a desirable amenity offering convenience, security, and energy efficiency.

- Built-in Safety Features: Advanced electric shutters often incorporate crucial safety features. These can include automatic locks that engage when the shutter is fully closed, obstacle detection sensors that halt the shutter's movement if an object is in its path (preventing damage or injury), and manual override functions for emergency operation during power failures. Many models also offer integrated battery backup systems to ensure functionality during outages.

Cons of Electric Roller Shutters

Despite their numerous benefits, electric roller shutters do have some disadvantages:

- Higher Initial Cost: Electric shutters represent a larger upfront investment. Their purchase and installation costs are significantly higher due to the inclusion of motorized components, complex electrical wiring, and the necessity of professional installation. Residential electric window shutters can range from £300 to £700 per window, while electric roller garage doors typically cost between £1,350-£2,400, with larger industrial models exceeding £5,000.

- Power Dependency: Electric roller shutters rely on a consistent electricity supply for operation. In the event of a power outage, they may become inoperable unless a battery backup system or a solar-powered option is installed. This dependency can be a critical consideration in areas prone to frequent electrical interruptions.

- Potential for More Complex Repairs: The electrical components, such as motors, wiring, and control boards, are more susceptible to wear and tear or technical faults over time. Diagnosing electrical issues or replacing a malfunctioning motor requires specialized skills and can lead to higher repair costs (e.g., motor replacement typically costs £400-£500) and potential downtime if the shutter is critical to operations.

Typical Use Cases

Electric roller shutters are ideally suited for environments where convenience, automation, and robust security are paramount:

- Large Windows & Doors: They are the preferred choice for openings where manual operation would be impractical or difficult due to the sheer size or weight of the shutter.

- Modern Homes & Businesses: Electric shutters align perfectly with contemporary properties and lifestyles that prioritize convenience, integrated automation, and a sleek, minimalist aesthetic.

- High-Security Requirements: Benefiting from enhanced motor locking mechanisms and the potential for integration with alarm systems, electric shutters provide superior protection for high-value assets or sensitive areas.

- Frequent Use Applications: In commercial establishments, loading docks, or residential garages used multiple times daily, the speed, efficiency, and time savings offered by electric operation are invaluable.

- Individuals with Mobility Issues: The effortless, push-button operation of electric shutters greatly improves accessibility, making them an excellent choice for individuals with physical limitations.

Maintenance & Common Problems

While electric roller shutters offer daily convenience, their sophisticated components necessitate specific maintenance considerations to ensure long-term performance and reliability.

- Stricter/Professional Maintenance: Motorized and electrical components require more intensive upkeep compared to manual systems to maintain smooth operation and ensure longevity. A professional service is recommended at least once a year for residential shutters. For high-usage commercial environments or those exposed to harsh conditions, more frequent checks (bi-annual or quarterly) are advisable.

- Motor Maintenance: The motor is the core of an electric roller shutter system and is crucial for its functionality. It should be regularly inspected (at least annually) for signs of overheating, unusual noises, or slow operation to prevent premature motor burnout. The typical lifespan of a roller shutter motor ranges from 5 to 15 years, depending on factors such as usage frequency, quality of the motor, and consistency of maintenance.

- Battery Backup Testing: If the electric shutter system includes a battery backup for power outages, these batteries should be tested regularly, ideally every six months, to ensure they are holding a charge and are fully functional when needed.

- Common Problems:

- Malfunctioning Motor: This is a key issue for electric shutters, leading to slow or jerky movement, unusual noises, or complete failure to operate. Common causes include overuse, overheating, or worn-out internal parts of the motor.

- Power Source Failure: Problems with the main electricity supply, internal wiring, or tripped fuses can interrupt the shutter's operation.

- Remote Control Issues: Unresponsive remote controls, signal interference, or simply dead batteries are common problems that can prevent effortless operation.

- Proximity Sensor Problems: Faulty, blocked by dirt or debris, or misaligned sensors can cause the shutter to stop unexpectedly during movement or fail to close fully, compromising safety and security.

- General Wear & Tear: Similar to manual shutters, components such as slats, tracks, weather seals, cables, or springs can wear out over time, especially without proper maintenance.

- Lifespan: Electric roller shutters, when properly maintained, can offer superior longevity and durability compared to manual systems. They often last between 10 to 20 years, with high-end models potentially exceeding 25 years. Regular professional maintenance is paramount to achieving this extended lifespan and ensuring consistent performance.

- While some might perceive electric shutters, especially battery-operated "smart drive" models, as "almost maintenance-free" due to less frequent direct user intervention, this perspective requires clarification. The convenience of electric operation means the end-user performs fewer routine tasks like manual lubrication or strap adjustments compared to a manual system. However, the complex internal components, such as the motor, electrical wiring, and sensors, are sophisticated mechanical and electronic parts that are subject to wear and tear. These components require specialized professional servicing to ensure optimal performance, extend their lifespan, and prevent costly breakdowns. Therefore, while the burden of daily hands-on maintenance for the user is reduced, property owners should anticipate and budget for the necessity of professional servicing for electric systems, which represents a different, often more specialized, kind of maintenance commitment.

Cost Analysis: Upfront, Installation, and Long-Term Value

The financial commitment for roller shutters extends beyond the initial purchase price, encompassing installation, running costs, and maintenance over their lifespan.

- Upfront & Installation Costs: Manual shutters are consistently the more affordable option for initial investment and installation. For residential window applications in the UK, basic manual shutters can start from approximately £700-£1500 , while a steel manual shutter might begin around £1,000. Manual roller garage doors, including supply and installation, typically range from £750-£1,400.

In contrast, electric shutters demand a higher initial investment due to the cost of the motor, associated wiring, and the more complex installation process that often requires professional expertise. Residential electric window shutters in the UK can range from £600 to £1500 per window. Electric roller garage doors typically cost between £1,350-£2,600, with high-quality insulated options generally falling within the £2000-£3,000 bracket. Larger or specialized electric industrial models can exceed £5,000. The labor cost for installing an electric garage door alone is estimated to be between £350-£650.

- Running Costs: Manual shutters incur virtually no running costs, aside from the occasional purchase of lubricants for maintenance. Electric shutters, while requiring electricity, draw minimal power. For instance, the annual electricity usage for an electric garage door is estimated to be a negligible 44-70 kWh, translating to very low running costs, typically £10-£20 per year.

- Long-Term Value & Maintenance Costs: While manual shutters appear cheaper upfront, electric shutters often offer better long-term value and can be more cost-effective over their lifespan. This long-term cost-effectiveness is not solely attributed to energy savings from insulation (which is primarily material-dependent). Instead, it stems significantly from the operational efficiency and reduced labor and time costs for the user or business. For commercial settings, the time saved in opening and closing heavy shutters translates directly into reduced staff costs and improved workflow efficiency. For a homeowner, the convenience and automation free up personal time and eliminate physical strain. This broader perspective of "true cost" includes both tangible financial aspects (minimal electricity consumption, potential for higher resale value) and intangible benefits (convenience, time savings, reduced physical effort, enhanced security features), which can collectively outweigh the higher initial investment and professional maintenance requirements.

Manual shutters generally have lower typical repair costs and shorter labor times for repairs due to their simpler mechanics. However, they may wear out faster with heavy use or inadequate maintenance. Electric shutters, while having slightly higher typical repair costs (e.g., motor replacement at £400-£500 ) and potentially longer labor times for complex electrical diagnostics, are often built with more durable components designed to handle daily use more smoothly if properly maintained. Annual maintenance for electric garage doors can start around £99.95 , with motor servicing recommended every 2-3 years at a cost of £50-£100. Over a 10-year period, the total lifetime costs for manual garage doors might range from £100-£250, whereas electric ones could be £300-£600.

Reliability & Lifespan

The reliability and expected lifespan of roller shutters are influenced by their design, material quality, frequency of use, environmental conditions, and crucially, the level of maintenance they receive.

- Overall Lifespan: Roller shutters generally have a robust lifespan, typically lasting between 10-25 years. High-end models, particularly those made from quality materials like aluminium (which is corrosion-resistant) or steel (known for strength), can even reach 25-30 years with diligent care.

- Manual Reliability: Manual shutters are often considered reliable due to their mechanical simplicity and fewer complex parts. Their operation is independent of power grids, ensuring functionality during blackouts. However, they are more susceptible to wear and tear directly from physical operation. The repetitive stress on components like cables, straps, and winding mechanisms can lead to issues such as breakage or jamming over time, particularly with heavy use or if maintenance is neglected. This means that while the core system is simple, the parts subjected to direct human force can wear out faster.

- Electric Reliability: Electric roller shutter motors typically have a lifespan of 5-15 years, depending on usage frequency, motor quality, and maintenance consistency. While electric systems incorporate more complex components (motor, wiring, sensors) that could potentially fail, these systems are often engineered for durability. The smooth, automated operation reduces the physical stress and friction on the shutter curtain and tracks compared to manual systems, potentially leading to a longer lifespan for these core components. The long-term reliability of electric shutters is highly contingent upon regular professional maintenance, which addresses the specific needs of their motorized and electrical parts.

- Impact of Maintenance: Consistent upkeep, including routine cleaning, periodic lubrication, and regular professional inspections, significantly extends the lifespan and ensures optimal performance for both manual and electric roller shutters. Conversely, poor installation can lead to numerous operational problems and prematurely reduce the shutter's lifespan.

Energy Efficiency & Noise Reduction

As previously highlighted, the primary factors driving a roller shutter's effectiveness in energy efficiency and noise reduction are the material properties of the shutter curtain and the quality of its installation, rather than the method of operation.

- Insulation: When closed, roller shutters create an additional insulating barrier over windows and doors. This can significantly increase the R-value (thermal resistance) of the opening, potentially more than doubling it (e.g., a window's R-value of 2.1 can increase to 4.25 with a closed shutter). This substantial improvement directly translates into reduced heat transfer, leading to considerable energy savings on heating and cooling costs.

- Noise Reduction: Insulated roller shutters, especially those with foam-filled slats, are highly effective at dampening external noise. They can reduce outside sound by a significant margin, with figures indicating reductions of up to 35 dB or even 50%. This capability can transform a noisy environment, such as a home near a busy road, into a much quieter and more peaceful space. A tight seal, achieved through precise and professional installation, is absolutely crucial for maximizing these noise-blocking benefits by eliminating gaps where sound could leak through.

- Operational Noise: While the core noise reduction benefit comes from the shutter's physical properties, there is a difference in the noise produced during operation. Electric shutters generally operate more quietly due to advanced motor technology, offering a smoother and less intrusive experience compared to the mechanical sounds (e.g., winding, rattling) that can accompany manual operation.

Making Your Choice: Key Factors to Consider

The decision between manual and electric roller shutters is a personal one, influenced by a blend of practical, financial, and lifestyle considerations. To make the best choice, property owners should carefully evaluate the following factors:

- Budget: Assess your initial investment capacity and your willingness to pay a higher upfront cost for the long-term convenience and advanced features offered by electric systems.

- Size and Weight of the Shutter: For very large or heavy openings, manual operation is often impractical and unsafe. Electric operation becomes a necessity for such applications, as it effortlessly handles the weight and size.

- User Mobility & Convenience: Consider who will be operating the shutters and how frequently. Electric shutters offer effortless, push-button operation, making them ideal for everyone, including individuals with physical limitations or those who simply desire maximum convenience.

- Importance of Automation & Smart Home Integration: If scheduled operation, remote control from a distance, or seamless integration with existing smart home systems (like voice control or mobile app management) are priorities, electric shutters are the only viable option.

- Power Reliability: In geographical areas prone to frequent power outages, manual shutters guarantee continuous operation and security. Alternatively, if electric is preferred, ensuring the system includes a reliable battery backup is essential to maintain functionality during power interruptions.

- Security Priorities: While both types offer security, electric shutters often provide enhanced features such as robust motor locking mechanisms and the potential for integration with alarm systems, offering a higher level of protection for properties with elevated security needs.

- Impact on Property Value: Electric shutters, with their modern amenities and convenience, can significantly increase a property's curb appeal and potentially enhance its resale value.

- Maintenance Preference: Consider your comfort level with maintenance tasks. Are you prepared for simpler, more frequent DIY maintenance (cleaning, lubrication) or do you prefer the convenience of less frequent user intervention but the necessity of professional servicing for complex systems?.

Can You Upgrade Manual to Electric?

Yes, in most cases, existing manual roller shutters can be upgraded to electric operation. This typically involves installing a suitable motor within the roller tube and integrating the necessary electrical components and control mechanisms (such as wall switches or remote controls). This upgrade can be a cost-effective and viable option if a property owner's needs change, or if they wish to add the convenience of automation without the expense of a complete shutter replacement. However, it is always essential to consult with a qualified professional to assess the feasibility, compatibility, and overall cost-effectiveness of upgrading a specific manual system.

Conclusion

The choice between manual and electric roller shutters is not a universal "best" solution; rather, it is a decision that fundamentally depends on the individual needs, budget, lifestyle, and specific characteristics of a property.

Manual roller shutters offer a compelling blend of affordability, mechanical simplicity, and independence from power, making them an excellent choice for smaller openings, budget-conscious installations, or areas with unreliable electricity. Their straightforward design often translates to simpler, more manageable maintenance tasks for the homeowner.

Conversely, electric roller shutters provide unmatched convenience, advanced automation capabilities, enhanced security features, and suitability for larger openings. While they require a higher initial investment and depend on a power supply, their long-term value often comes from the significant time and effort savings they provide, along with their potential to increase property value. The maintenance for electric systems, while less frequent for the user, necessitates professional attention for their complex motorized components.

By carefully weighing the pros and cons of each type, considering factors such as the size of the opening, user mobility, desired level of automation, and long-term financial implications, property owners can confidently select the roller shutter solution that best enhances the security, comfort, and efficiency of their home or business.

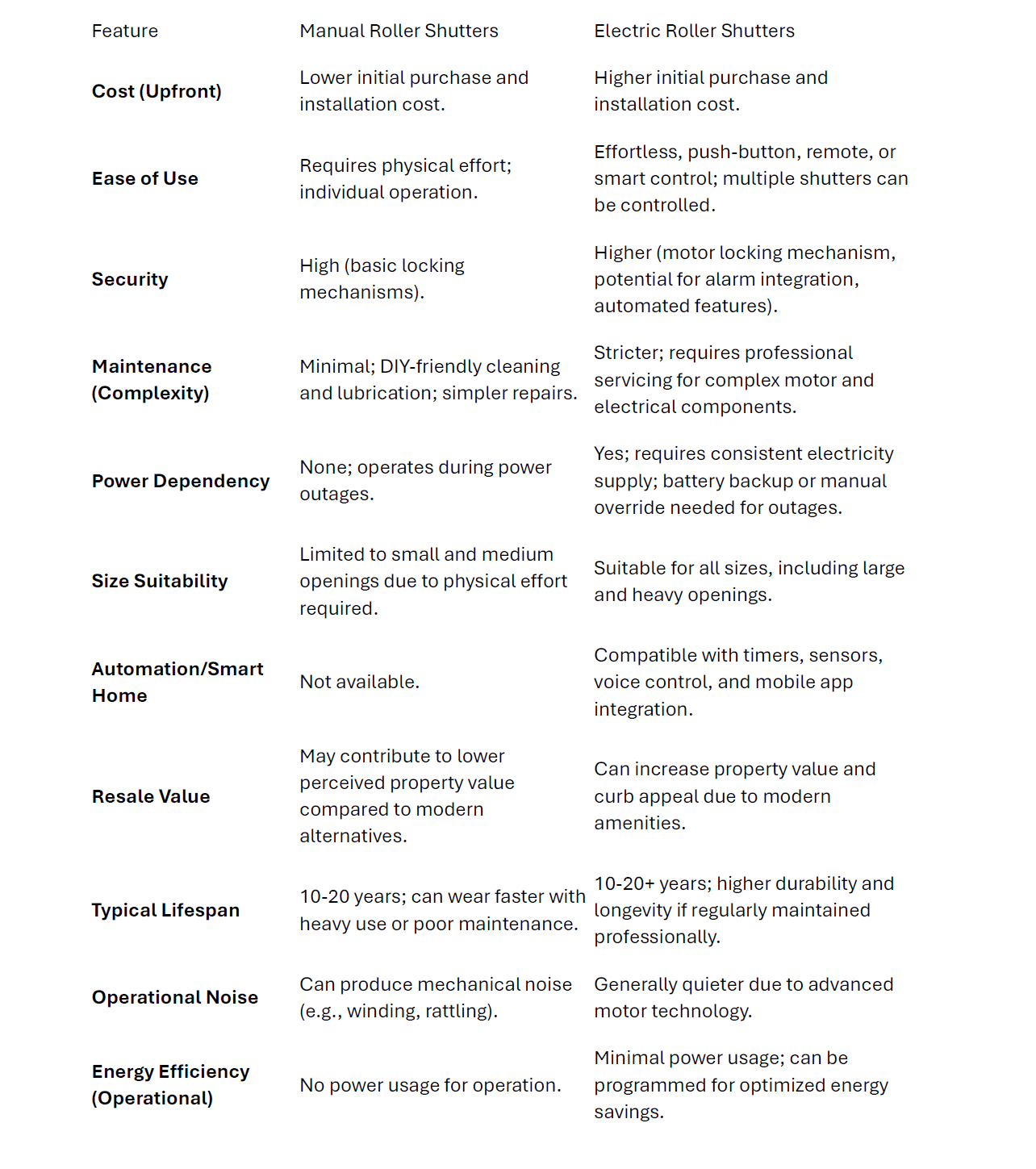

Direct Comparison: Manual vs. Electric Roller Shutters

Choosing between manual and electric roller shutters involves weighing various factors, from initial investment to daily convenience and long-term upkeep. The following comparison highlights the key distinctions.

Contact us

01392270218 - info@roller-shutter.uk

Have a Question? Talk to Our Shutter Specialists